The easy way to implement a management system

Linking best practice, internal and external standards to manage knowledge

Drilling Management System

See how one client benefitted from an easy- to-use compliance system that exploits company knowledge, by sharing best practice well delivery throughout the organisation – connecting process to engineers.

The Challenge

The client, an independent exploration and production company based in Scotland and employing over 400 people, required a solution to manage the process of drilling wells that leveraged company knowledge, proprietary best practices, and external industry best practice (e.g. ISO and API Standards), while adhering to local government regulatory requirements. The solution needed to support improved well integrity through appropriate design, supervision and control of well delivery.

Flare’s Approach

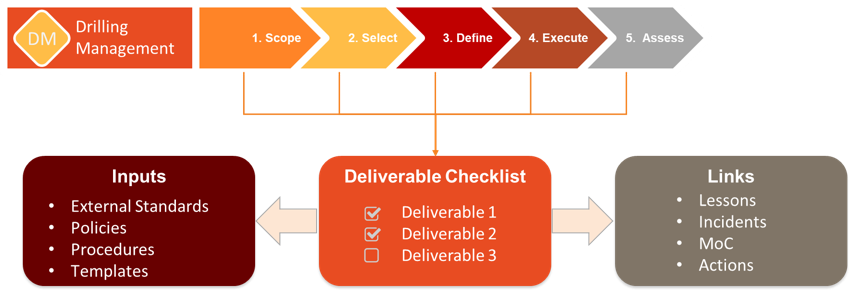

Flare worked with the client to develop best practice for well delivery in the organisation. This included on-site workshops and discussions to define the delivery process, identify the deliverables required, using a stage-gate process. For each deliverable, consideration was given to how company policy, external standards, and relevant legislation was linked. This led to the definition of company best practice for well delivery.

The solution provided a web-based interface to the Drilling Management System (DMS), from which the management team could see the status of each well being drilled and have easy access to the deliverables produced, with an easy to use interface guiding drilling engineers and operations geologist through the best practice process of designing and drilling a well.

This project was a digital transformation, taking a business process, previously communicated through manuals and turning it into an application to assist all stakeholders.

Benefits/Outcomes

- Management Views – The DMS (Drilling Management System) interface made it easy for the management team to see the status of each well being drilled, access design documentation and operations reports, and view an audit trail of drilled wells and their compliance with the process.

- Role-based dashboards for HQ and rig-site engineers made it easy to view and use the entire drilling process for campaigns and individual wells. Views show what and when deliverables are required, and users, can access locally held policies and procedures, regardless of where they are in the world.

- Frictionless Information management via intelligent search makes it much easier to find documents or share documents and visualise stage gate status (progress) of each well. Publishing of documents is handled by dragging and dropping files, which results in automatic security, descriptive tagging and routing of the content. Content can be routed automatically into intermediate stores or corporate stores based on business rules.

- The system has a flexible architecture that utilised components of Sirus and Tracker, so that published documents inherit tags on publication for future ease of discovery, users receive reminder notifications for deliverables, and dashboards of progress were available. The system could also be deployed on stand-alone laptops so that rigs with poor communications could also utilise the system.

- The client could leverage the underlying Sirus platform (intelligent search, drag and drop publishing, automatic tagging, metrics and dashboards) in other areas of the business, allowing for rapid deployment of future, fully integrated and extensible information management

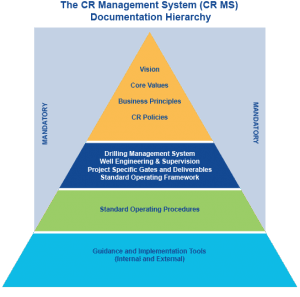

- The solution was successful and extended, using a similar approach to capture deliverables for the Corporate Responsibility Management System.